Description

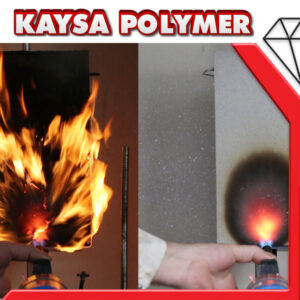

Process aid production

buy Polymer Processing Aid as one of the polymer additives is done by Kaysa Polymer Company with more than 20 years of experience in the petrochemical industry. Kaysa Polymer with the motto “We compete with our quality” is known as a manufacturer and exporter of colored, white, and black masterbatch, polymer compound, and polymer additives such as selling process aids in the Middle East. To develop the quality and increase the effectiveness of its products, Kaysa Polymer has defined special standards for itself in the production field. Using modern European technology and equipment, we have improved the quality of our products, especially colored masterbatch and polymer compounds. Our products are fully standardized to be compatible with various advanced processing techniques such as extrusion, injection molding, blow molding, thermoforming, and roto molding.

Polymer Processing Aid or PPA is an additive that is added to facilitate processability and improve some of the final properties of the polymer in various production processes such as extrusion, injection, and blowing.

Benefits of Process Aid (PPA)

- Improving the quality of the surface: using the help of processes can reduce the surface roughness of extruded polymer products and help create a smooth and uniform surface.

- Increasing melt stability: the help of the polymer process can improve the stability of the polymer melt against thermal and mechanical stresses and prevent phenomena such as melt fracture (sharkskin).

- Improving the optical properties and transparency of the product

- Improved particle dispersion: Helping to disperse materials better. PPAs can help to improve the dispersion of reinforcing or filler particles in the polymer matrix in composites. This leads to improved mechanical and thermal properties of the final composite.

- Reducing the friction between the polymer melt and the wall of the mold or equipment: this makes the flow of the melt smooth, reduces the pressure of the process, and improves the quality of the final surface of the product. Some process aids, such as fluoropolymers and silicone oils, reduce friction with molds and metal surfaces by being placed on the polymer surface and prevent mold wear.

- Reduced production costs: By increasing process speed and reducing waste, polymer process aids can reduce overall production costs.

Factors affecting the price of polymer process aid

The price of polymer process aid (PPA) depends on various factors that can be divided into the following general categories:

1. Type of process assistance:

• Type of base resin: The price of PPAs is different based on the type of base resin, such as polyethylene, polypropylene, polyvinyl chloride, etc. In general, PPAs based on more expensive resins such as polycarbonate and ABS are more expensive.

• Type of function: the help of polymer processes have different functions such as lubricant, stabilizer, anti-adhesion, nucleating, etc. PPAs with more complex and specialized functions are usually priced higher.

• Quality: The quality of the process aid depends on factors such as purity of raw materials, production process, and quality control. Higher-quality PPAs, which are produced from high-quality raw materials and with precise processes, are more expensive.

2. Market factors:

• Supply and demand: The price of polymer process aid is influenced by supply and demand in the market. If the demand for a particular type of PPA is high and its supply is limited, its price will increase.

• Currency fluctuations: The prices of raw materials for PPAs, especially base resins, are often in dollars. Exchange rate fluctuations can significantly affect the price of PPAs in the domestic market.

• Transportation costs: The costs of transporting PPAs from the place of production to the final destination also affect their price.

3. Other factors:

• Brand: PPAs from reputable and well-known brands in the market are usually priced higher due to their reliable quality and performance.

• Minimum order: Some PPA suppliers charge a higher price for orders with small volumes.

• Payment terms: Payment terms such as cash or credit can also affect the price of PPAs.

applications

Polyethylene films

Drip irrigation pipes

High-pressure polyethylene pipes

wire and cable

Why Kaysa Polymer?

Over the past two decades, Kaysa Polymer has become one of the leading producers of color, white, and black masterbatch and plastic additives and polymer compounds in the Middle East market. Kaysa Polymer satisfies its domestic and international customers by providing solutions for technical challenges by global standards as well as customized colors. Our main focus is on the production of colored, white, and black masterbatch, plastic additives, and various polymer compounds, especially calcium carbonate and talc compounds.

The achievements gained during the years of experience enable us to produce quality and affordable products. The bases of Kaysa Polymer polymer products are:

Low and high polyethylene (HDPE, LDPE, LLDPE)

Polypropylene (PP) base

Polystyrene (PS), especially HIPS

Acrylonitrile Butadiene Stern (ABS)

Nylon

To place a bulk order or to produce a prototype, please call +989034719105.

Reviews

There are no reviews yet.