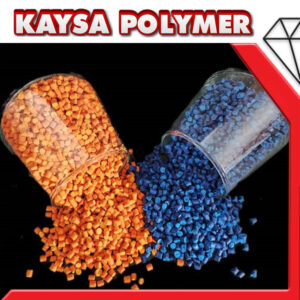

Buy color masterbatch

- Products

- Buy color masterbatch

Buy color masterbatch

Color masterbatch technical specifications:

| Color | MFI | Bases Application |

|---|---|---|

| BLUE | 10-18 | HDPE, LDPE, PP |

| GREEN | 10-18 | HDPE, LDPE, PP |

| RED | 10-18 | HDPE, LDPE, PP |

| YELLOW | 10-18 | HDPE, LDPE, PP |

Category Sale masterbatch

Reviews

There are no reviews yet.