Shop Premium Plastic Masterbatch on Sale Now!

- Products

- Shop Premium Plastic Masterbatch on Sale Now!

Showing all 4 resultsSorted by popularity

Important criteria when selling & buying masterbatch

When buying and sale masterbatch, some of the most important criteria to consider are:

Quality and Consistency

Masterbatch must be of high quality to ensure consistent color, performance, and properties in the final plastic product.

Look for reputable manufacturers with stringent quality control processes.

Color Accuracy and Consistency

The masterbatch should be able to accurately reproduce the desired color shade and maintain color consistency across production batches.

Manufacturers should have a database of color formulations and provide samples.

Heat Resistance and Temperature Stability

Masterbatch pigments and additives must withstand high processing temperatures without degradation or color shift.

Specify the maximum temperature requirements for your application.

Lightfastness and Weather Resistance

For outdoor applications, the masterbatch should contain pigments with high lightfastness ratings and resistance to UV radiation and weathering effects.

This ensures color longevity and product durability.

Migration Resistance

To prevent color migration or transfer between layers, choose masterbatches specifically designed for your polymer type and processing conditions.

Compatibility with Base Polymer

The masterbatch carrier resin must be compatible with the base polymer used in your application for proper dispersion and performance.

Dosing Accuracy and Dispersion

Masterbatches should allow for accurate dosing and uniform dispersion of additives throughout the plastic matrix, even at low addition rates.

Regulatory Compliance

Ensure the masterbatch complies with relevant regulations and standards for your industry and product applications, especially for food contact or medical uses.

By considering these important criteria, you can select the right masterbatch supplier and formulation to meet your specific product requirements for color, performance, and longevity.

What is masterbatch

What is masterbatch? Masterbatch is a concentrated mixture of pigments and/or additives blended and extruded together in a carrier resin or polymer matrix.

It is used to add color or impart other properties to plastic products during manufacturing.

Masterbatch serves two main purposes:

Coloring plastics (color masterbatch): Color masterbatches contain pigments or dyes dispersed in a carrier resin, allowing for the coloring of plastic products.

The carrier resin is compatible with the main plastic being processed.

Imparting other properties (additive masterbatch): Additive masterbatches contain functional additives like UV stabilizers, flame retardants, antioxidants, etc. dispersed in a carrier resin.

These enhance specific properties of the final plastic product.

masterbatch supplier

Are you looking for a reliable and efficient masterbatches supplier? Kaysa Polymer, with its brilliant experience and expertise in the polymer industry, is one of the market leaders and the best option for supplying quality masterbatches for various industries.

Why Kaysa Polymer?

At Kaysa Polymer, we care about quality, experience, and customer satisfaction. Utilizing the most advanced technologies and a team of outstanding experts, we can produce masterbatches with the right color, additives, and physical properties to match our customers’ needs.

Our products

Our masterbatches include a variety of colors and special additives, allowing you to produce your final products with unique features and high performance. We offer masterbatches for various industries.

• Plastics Industry

• Packaging

• Plastic Film Production

• Automotive Industry

• Electrical and Electronic Equipment

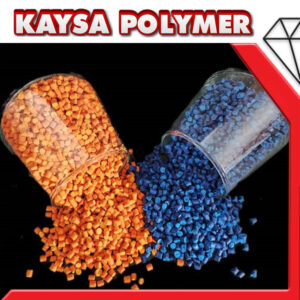

Color Masterbatch

In today’s competitive world, the quality and beauty of products, especially in the plastic and coloring industry, are of particular importance. To meet these needs, we are proud to introduce you to Color Masterbatch; a new product that, through advanced technologies and special formulations, can give your products unique color and beauty.

Outstanding Features of Color Masterbatch:

- Unparalleled Color Variety: Kaysa Polymer’s color masterbatches are custom-produced in a wide range of colors and types to match your specific needs. Whether you are looking for vibrant and cheerful colors or soft and classic colors, we have the right solutions.

- Superior Quality: Masterbatches produced using the best raw materials and modern technologies are at a high level not only in terms of color but also in terms of stability and durability. This feature assures you that your products will be resistant to environmental factors and erosion.

- Ease of use: The intelligent formulation of our color masterbatch allows for easy and quick use. You can easily add it to your production process without the need for major changes to your production lines.

- Technical support and expert advice: Our specialized team is always ready to help you make the best choice by providing technical and expert advice. We will be by your side to ensure that your production process is implemented in the best possible way.

White Masterbatch

White Masterbatch is a combination of white pigments (titanium dioxide) with a polymer base that is used to improve the color and brightness of plastic products. This material is specifically designed for products such as plastic films, disposable containers, and colored products. By using white masterbatch, you can achieve desirable features such as increasing color intensity, improving coverage, and reducing production costs.

This additive is easily combined with various types of polymers and enables the production of diverse products. From producing high-quality products to more economical products, a white masterbatch is a suitable option for any application.

With years of experience in the field of masterbatch production, Kaysa Polymer complies with international quality and standards in all its products. We produce white masterbatch using modern technologies and quality raw materials, which ensures that you will receive a quality and efficient product.

Join us and benefit from the unique benefits of white masterbatch 20 to 70% titanium dioxide. Relying on our expertise and experience, take your products to a new level of quality and customer satisfaction. For more information and expert advice, contact our sales team. We are ready to help you make the best decisions for the success of your business.

Black Masterbatch

Are you looking for a way to enhance the quality of your products? Do you want to dramatically improve the color and appearance of your products with a strategic choice? Black Masterbatch is the answer to your needs that can significantly impact the performance and beauty of your final product.

Black Masterbatch is designed as a polymer-based solvent, with a combination of quality black pigments (carbon black) and carrier materials, to bring your final products to the market with a rich and deep color. This product not only acts as a commercial color, but also provides performance enhancers such as UV resistance, thermal stability, and flexibility.

As one of the pioneers in the black masterbatch production market with a carbon black content of 25 to 40%, we offer a quality yet cost-effective product by utilizing modern technologies and rigorous testing. Our expert team, with extensive experience and knowledge in this field, is ready to assist you in all stages of purchasing and using black masterbatch.

Additive Masterbatch

Are you looking to improve the quality of your products? Do you want to add unique features to your products? Additive Masterbatch is your answer!

As a leader in the production of various additive masterbatches such as process aid, anti-UV, anti-block, lubricant, flame retardant, clarifier, filler, etc., Kaysa Polymer, relying on the experience and technical knowledge of its experts, offers the best compounds with the highest quality standards and following market needs. Cooperating with us ensures that you receive the best raw materials with the highest quality.

Quality at Every Stage

Quality assurance at all stages of masterbatch production is our priority. We implement strict quality control processes to ensure that our products meet international standards in terms of performance and durability.

On-time Delivery and Customer Service:

We stick to our schedule and commitments. Kaysa Polymer has established a strong and effective supply chain to ensure timely and uninterrupted delivery of masterbatches. Also, our customer service team provides necessary guidance according to your needs and requests.

Our goal is to build strong and long-term relationships with our customers. We assure you that purchasing masterbatches from Kaysa Polymer will not only be an economic investment but also a positive step towards improving the quality and performance of your products.

Without a doubt, choosing Kaysa Polymer as your masterbatch supplier will be an effective step toward the growth and progress of your business. Join us and benefit from our unparalleled quality, diversity, and services. For more information and free consultation, contact us and start a successful and sustainable partnership.

the wholesale price of masterbatch

Here are some factors that can affect the wholesale price of masterbatch:

Resin type:

The resin used in the masterbatch will be a major cost factor. Resins such as polypropylene (PP), high-density polyethylene (HDPE), and low-density polyethylene (LDPE) are typically less expensive than engineering resins such as nylon, ABS, or PC.

Colorant type and loading level:

The type and amount of colorant used in the masterbatch will significantly impact the price. Organic pigments are generally more expensive than inorganic pigments. The amount of colorant needed to achieve the desired color will also affect the cost, with higher loading levels costing more.

Additive type and loading level:

Similar to colorants, the type and quantity of additives included in the masterbatch will influence the price. Antioxidants, UV stabilizers, flame retardants, and other additives can vary greatly in cost.

Minimum order quantity (MOQ):

Some suppliers may have a minimum order quantity (MOQ) for masterbatches. This can affect the price per unit, as smaller amounts may be more expensive.

Lead time: The lead time for masterbatch can vary depending on the supplier and the type of masterbatch. Shorter lead times may come at a premium cost.

Demand and supply for sale masterbatch:

Market forces of supply and demand can also affect the price of masterbatch. If there is a high demand for a particular type of masterbatch and a limited supply, the price will likely be higher.

Manufacturer and brand reputation:

Masterbatches from well-known and reputable manufacturers may command a higher price due to perceived higher quality and consistency. Kaysa Polymer Company, a producer of masterbatch and polymer compounds, offers you the best price and quality. To know the price, contact the company number +982122500033 or WhatsApp number 989125436521.

Custom vs. standard formulations: Custom masterbatches formulated to meet specific customer requirements will typically be more expensive than standard off-the-shelf products.

Here are some additional points to consider:

Wholesale prices are typically negotiated between the buyer and seller and may be influenced by factors such as the size of the order, the customer’s creditworthiness, and the supplier’s current production capacity.

It is important to get quotes from several suppliers before purchasing to compare prices and ensure you are getting the best value for your money.

Where to buy bulk Masterbatch?

You can buy bulk masterbatch from a few different places:

Online Marketplaces: You can find online marketplaces that connects buyers and sellers from all over the world. You can find a wide variety of masterbatch suppliers on Internet, including many that sell in bulk quantities.

Plastic distributors: Many plastics distributors sell masterbatch, including both small and bulk quantities. You can find plastics distributors in your area by searching online or in industry directories.

Masterbatch manufacturers: Some masterbatch manufacturers also sell directly to customers. You can find a list of masterbatch manufacturers on industry websites or by searching online.

Here are some things to keep in mind when buying bulk masterbatch:

Minimum order quantity: Many suppliers have a minimum order quantity (MOQ) for bulk purchases. Be sure to check the MOQ before placing an order.

Shipping costs: Shipping costs can be significant for bulk purchases. Be sure to factor in the shipping costs when comparing prices from different suppliers.

Payment terms: Some suppliers may require payment in advance for bulk purchases. Be sure to understand the payment terms before placing an order.

Quality: It is important to buy masterbatch from a reputable supplier that offers high-quality products. Be sure to ask the supplier about the quality of their masterbatch and to request a sample if possible.